Information

Only blades without serrated edges can be sharpened: cleavers, knives, hatchets, scissors, and drill bits from 3–22mm in diameter. The blades are ground and then polished to razor sharpness on a leather honing wheel. Drill bits receive a special cross-grind, preventing them from wandering when starting a hole and significantly increasing their cutting lifespan compared to conventionally sharpened bits. The point angle, rake angle, and clearance angle can be adjusted to match the material being drilled, e.g., thin-walled, brittle plastics. It is recommended to include a sample of the material to be drilled for optimal results.

Drill bits can either be provided by the customer or sourced individually through wholesale suppliers (HSS standard drill bits). Upon request, the shank of the drill bit can be turned down on a lathe to fit smaller drill chucks (please specify the desired shank diameter under “Other”).

Please download, print, and complete the attached form, then include it with the tools to be sharpened and drop it off at the workshop. Only fully completed forms can be processed.

Current expenses for the sharpening service

Scissors: €3 per piece

Knives (blade length up to 10cm): €4 per piece

Knives (blade length over 10cm) and hatchets: €5 per piece

Drill bits:

3–6mm: €3

6–12mm: €4

12–22mm: €5

Shank reduction on lathe: €2

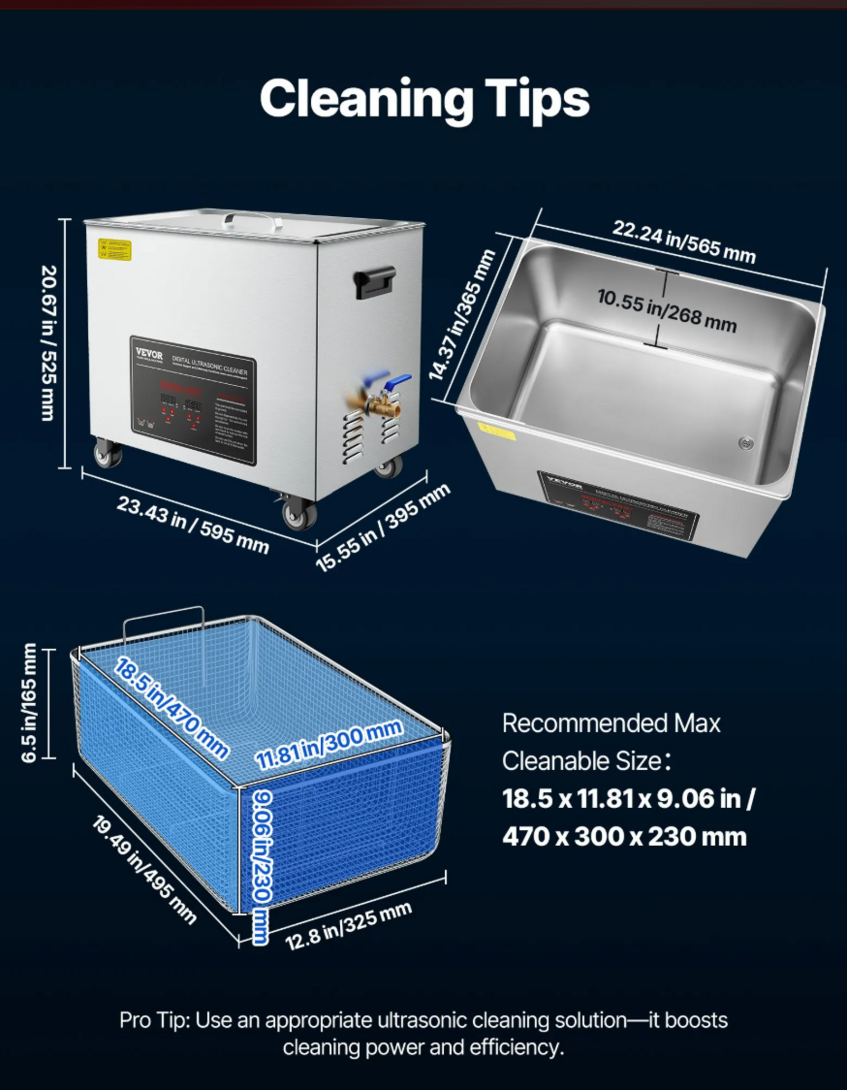

Ultrasonic cleaning bath

The workshop now offers a cleaning service using an ultrasonic cleaning bath.

In the workshop itself, this device is used for cleaning circular saw blades, for complex structures that cannot be cleaned manually, and for our protective lenses, which are made of plastic. When the lenses become dirty, they are no longer cleaned manually — which would inevitably cause scratches — but instead cleaned in the ultrasonic bath, rinsed with water, and then dried with compressed air.

This very gentle cleaning method prevents any scratches that could impair visibility and render the safety glasses unusable. As a result, the lifespan of the protective lenses increases significantly. This helps reduce costs and fully aligns with our commitment to sustainability. The basket of the cleaning device can hold at least 50 protective lenses at once.

For each cleaning cycle, the workshop currently charges a small fee of

€7 (for cleaning detergent). An environmentally friendly universal cleaner for metal, glass, and plastics is used.

Please place orders via the “Order Form” section on the workshop’s website.

How an ultrasonic cleaner works:

An ultrasonic cleaner operates through the process of cavitation:

high-frequency sound waves are sent through a liquid (usually water with a cleaning agent), creating tiny vacuum bubbles that collapse suddenly.

These implosions generate small pressure waves that dislodge dirt and deposits from the surface of objects, even in hard-to-reach areas.